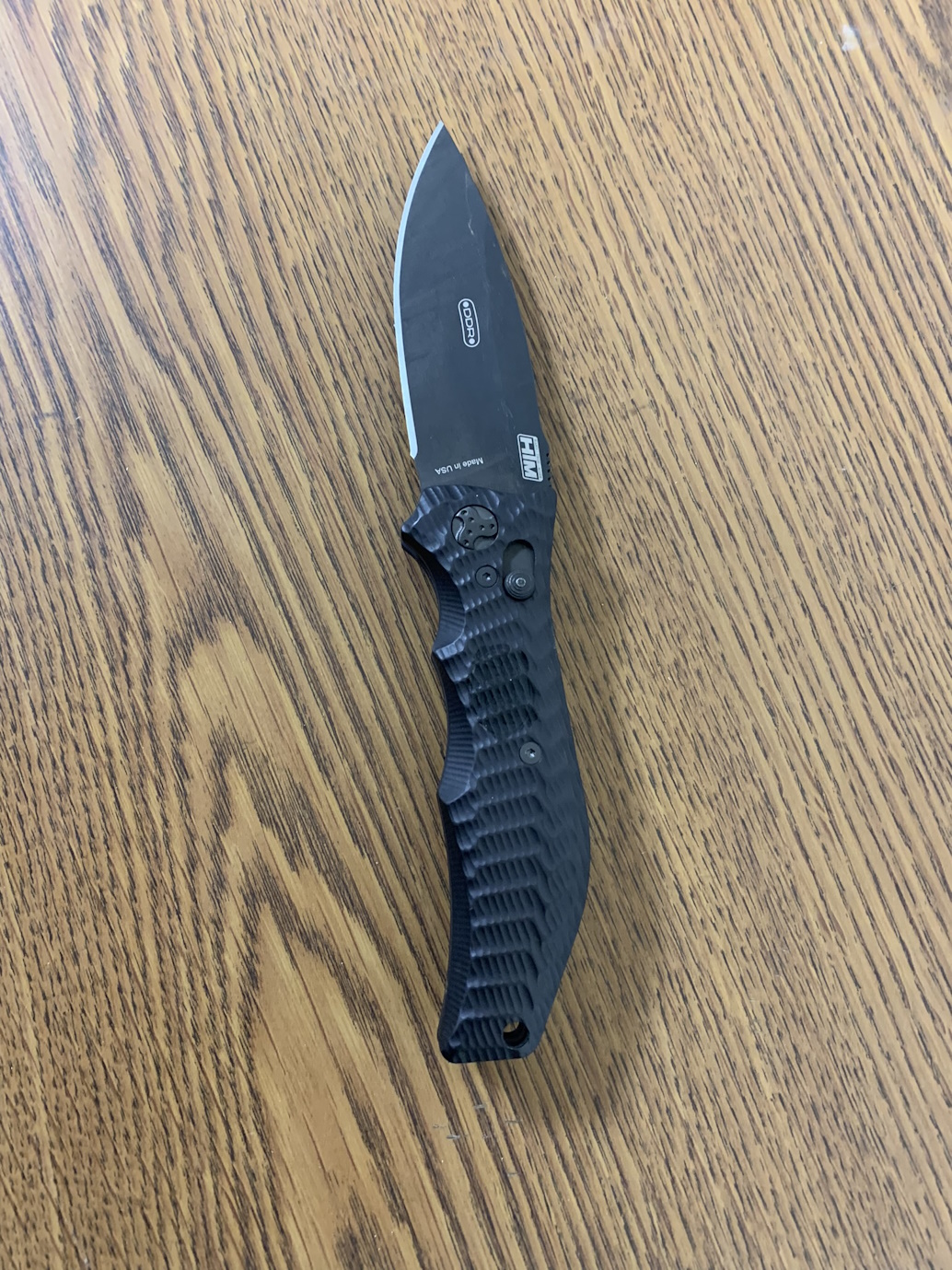

Custom switchblades, like other custom knives, can be crafted with a variety of features based on the preferences of the knife maker and the intended use of the knife. Switchblades, also known as automatic knives or push-button knives, have a spring-loaded blade deployment mechanism.

Custom switchblades may incorporate various locking mechanisms to ensure the blade stays securely open during use. Common mechanisms include liner locks, frame locks, button locks, and plunge locks.

A pocket clip is a practical feature for easy and secure carry. Some custom switchblades may have a reversible or adjustable pocket clip to accommodate different carry preferences.

Custom switchblades can be tuned for different opening speeds and deployment forces. Some users prefer a fast, snappy deployment, while others may prefer a more controlled and deliberate opening.

Many custom switchblades feature intricate engravings, personalized markings, or unique finishes on the blade or handle. These artistic touches add to the knife’s aesthetics and make it a distinctive piece.

Some custom switchblades are produced in limited quantities or as one-of-a-kind pieces, making them collectible and unique. Limited editions may include special features or materials not found in regular production models.

It’s important to note that the legality of switchblades varies widely by jurisdiction, so individuals should be aware of and adhere to local laws regarding the possession and use of automatic knives. Additionally, custom knives can be expensive and may require a wait time for the artisan to create the knife to your specifications.